Factors affecting the performance of breathable moisture permeability

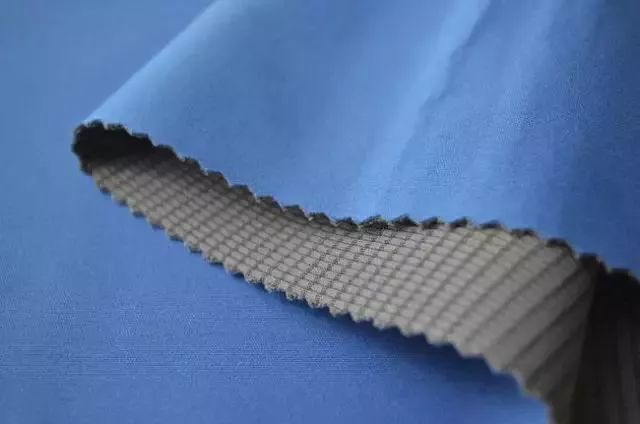

Composite fabric fabric breathable moisture permeability can be expressed in wet resistance, in the fabric fabric on both sides of the existence of water vapor concentration difference (or water vapor partial pressure difference), the resistance of water through the fabric called fabric fabric wet resistance.

The following formula is expressed.

R=C/q

R---- fabric fabric wet resistance;

q------ breathable moisture permeability speed (wet flow), kg/m2.s.

c---- water vapor concentration difference, kg/m3.

Under the stable diffusion state, the greater the wet resistance, the smaller the moisture permeability or moisture permeability velocity.

Influencing factors

1. The temperature and humidity conditions of the fiber

In the fabric structure (including the proportion of the volume of the fabric in the fiber) under the same conditions, fiber type on the fabric fabric resistance almost no effect, Hollis by hydrophilic treatment of polyester fabric and untreated polyester fabric for comparison experiments also show that under low humidity conditions, the transfer of water vapor and the fabric within the fiber type relationship is not obvious. Only in high temperature conditions by the hydrophilic treatment of polyester fabric moisture permeability is significantly better than the polyester fabric without hydrophilic treatment.

In fact, under low humidity conditions, due to the fiber itself less moisture absorption, and the diffusion coefficient of air than the fiber is much larger water vapor through the pores between the fabric to the side of the water vapor pressure is lower, indicating that the transfer of water vapor in the fabric and fiber type relationship is not significant. This time the thickness and porosity of the fabric or fabric structure is the main factor to determine the fabric moisture permeability.

On the other hand, the moisture absorption of fiber board is also related to the temperature.

In the process of moisture absorption, fiber moisture absorption to put a certain amount of heat, so that the temperature of the fiber aggregate has increased, the partial pressure of water vapor inside the fiber rose, reducing the gradient of the internal and external moisture concentration of the fiber, so that the fiber moisture absorption rate and diffusion of moisture permeability slowed down.

The diffusion coefficient of fibers will increase exponentially with the increase in temperature, and this increase is more obvious when absorbing moisture, so the increase in temperature and humidity will strengthen the moisture transfer capacity of fibers in the fabric. From the rate of moisture absorption or dehumidification, the general performance is faster at the beginning, with the increase in moisture absorption or dehumidification and gradually slow down, and finally reach the moisture absorption equilibrium. However, the time required to reach the equilibrium is related to the moisture absorption capacity of the fiber itself and the elasticity of the fiber aggregate; in addition, the thermal conductivity of the fiber will increase after moisture absorption, and the moisture permeability caused by the moisture absorption of the fiber itself is very complicated, and there is not yet a very sound theory to quantitatively describe.

2. Fabric thickness and coverage coefficient

The thickness of the fabric and its wet resistance has an approximate, generally the thicker the fabric thickness, the greater the fabric wet resistance. This is because the thicker the thickness of the fabric, the longer the path taken by water vapor through the pores between the fabrics. In addition, the fabric porosity changes on the fabric wet resistance is obvious.

3. The type of fiber and filling rate

In the case of high humidity or fabric structure more closely, water vapor is no longer just through the pores in the fabric transfer but by the fiber itself, then the type of fiber becomes an important factor affecting the fabric transfer.

On the one hand, the fibers themselves absorb moisture to produce swelling, making the fabric more compact, fabric permeability is weakened, relying on the pore diffusion moisture transfer role is reduced; on the other hand, compared with the cross-sectional area of the fabric, the surface area of the fiber plate is a considerable amount of orders of magnitude. Fiber moisture absorption is larger, moisture diffusion through the fiber surface, that is, capillary core suction effect is strengthened, become the main aspect of the fabric moisture transfer, fabric porosity reduction caused by diffusion moisture permeability reduced to become a secondary conflict.

Therefore, as long as the fabric fiber moisture rate to a certain extent, despite the reduction in pore space makes the fabric by the air medium moisture transfer reduced, but due to the fiber itself moisture transfer has a substantial increase of a few days, wet resistance or may be reduced.

And whether the fiber itself moisture transfer or capillary produced by the core suction moisture transfer are closely related to the hydrophilicity of the fiber and fiber surface properties. The test results show that under the same tightness conditions, different kinds of fibers of water vapor wetting resistance and the relationship between the degree of tightness of the fabric. Obviously in the tightness of the lower conditions, a variety of fiber fabric wet resistance difference is not large, when the density factor reaches 0.4 or higher than 0.4, the fiber surface is not smooth, fiber cross-section irregular, good moisture absorption of fibers, such as sheep, in the case of wool, with the fiber collection filling rate increases, the fabric wet resistance increase is small, the linear relationship between the fabric wet resistance and filling rate is good.

But for nylon, chlorine spandex, glass fiber and other chemical fibers, when the fill rate is larger (smaller porosity, larger capacity), such as fill rate greater than 39% or porosity less than 61%, fabric capacity greater than 0.98g/cm3 (for glass fiber fabric) wet resistance will increase sharply with the capacity, fill rate (or the reduction of porosity) surface. Moisture absorption of good cotton, wool and other fiber fabric wet resistance is significantly lower than the non-hygroscopic fiber fabric wet resistance, that is, the impact of fiber hydrophilicity on fabric moisture transfer is determined by the fabric tightness.

Therefore, the structure of the more loose, high void ratio of the fabric, in the case of low relative humidity of the air, regardless of whether its fiber moisture absorption, moisture permeability to diffusion through the gaps between fibers, yarns; and to a very small extent by the influence of fiber type, in the case of high relative humidity of the air, the moisture absorption of good fiber woven into a tight fabric, fiber moisture absorption and expansion to reduce the gap between fibers, diffusion of moisture permeability The proportion of reduced, the proportion of capillary moisture permeability within the fiber increases, capillary moisture permeability becomes the main factor.

4. Fabric finishing

Coating or impregnation and other fabric finishing will increase the wet resistance of the fabric. Because it increases the path of water vapor through the fabric or blocked the fabric void. However, hydrophilic finishing will increase the moisture permeability of the fabric. Water-repellent finishing generally does not affect the moisture permeability of the fabric.

5. Other factors

General fabric liquid water transmission rate is greater than the evaporation rate of the liquid surface, the inside of the fabric has a smaller gap pore to make it easy to condense into liquid water outward transport, the formation of differential capillary effect, the outside of a larger gap pore to make it easy to meet the evaporation conditions, conducive to moisture dispersion. Fabric surface liquid water evaporation capacity and fabric thickness, porosity and other less close relationship, but with the fabric surface concave and convex form, especially the size and depth of the surface pits have a close relationship, in general, the larger the pit opening area, the larger the radius of curvature, evaporation efficiency is super high. The details of the crater, wind speed, temperature difference, etc. also have obvious influence.

Contact: Jeanne yang(MISS)

Phone: 13912652341

E-mail: [email protected]

Add: Room A2216/A2217,Double-Star Building,No 567 New South Middle Road, KunShan City JiangSu Province ,China.