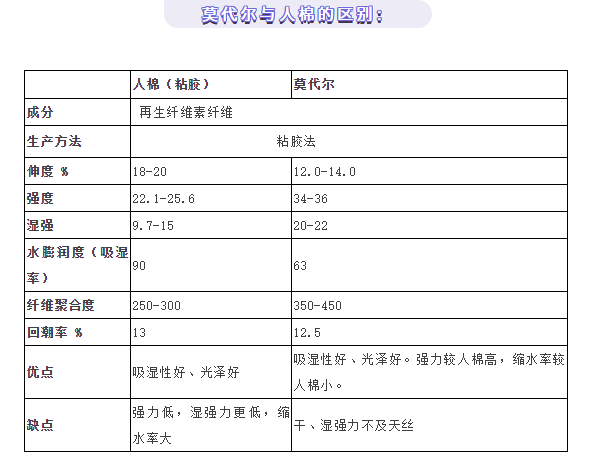

Modal and rayon are both recycled fibers, but the raw material of modal is wood pulp, while the raw material of rayon is natural fiber, from a certain point of view, both fibers are green fibers. In terms of feel and style, they are similar, but the price of the two is very different.

Modal

Modal fiber is a newly emerged fabric in recent years, also called: Modal, for short: Modal. It is a modern fiber that combines the luxury texture of natural fibers and the usefulness of synthetic fibers into one, with the softness of cotton, silk finish and smoothness of hemp, and its water absorption and breathability are better than cotton, with a higher dyeing rate and bright and full fabric color. modal fiber can be blended with a variety of fibers chemical fiber fabrics, interlaced, such as cotton, hemp, silk, etc., to enhance the quality of these fabrics, so that the fabric can maintain Soft, smooth, play the characteristics of their respective fibers to achieve better taking effect.

Rayon

Man-made cotton is the common name of viscose fiber, short: man-made cotton. Viscose fiber refers to the wood and plant ligustrum and other cellulosic raw materials extracted from the alpha-cellulose, or cotton staple as raw material, by finishing into spinning stock, and then wet spinning made of man-made fibers. In short, human cotton is a recycled fiber.

Modal is a cellulosic regenerated fiber of high moisture modulus viscose fiber developed by Lenzing, Austria. The raw material of this product is all natural material, harmless to human body and can be decomposed naturally, harmless to the environment. Modal fiber is made from wood pulp from the bush forests in Europe and then made through a deliberate spinning process, and is a cellulose fiber, so it is the same as cotton and is a pure natural fiber.

Modal products because it has a good softness and excellent moisture absorption, but its fabric stiffness poor characteristics. Now mostly used in the production of underwear. Modal knitted products are mainly used in the production of underwear. However, modal has a silvery white finish, excellent dyeability and bright color after coloring, enough to make it become the outerwear used. Because of this, modal is increasingly becoming a material for outerwear and decorative fabrics. In order to improve the shortcomings of pure modal products, modal can be blended with other fibers, and can achieve good results. With this spinning yarn woven into the blended chemical fiber fabric fabric, so that the cotton fiber more supple, and improve the appearance of the fabric. Modal can also be woven in the weaving process of woven fabrics and can be interlaced with yarns of other fibers to create a variety of fabrics. Modal products in modern workwear apparel has a wide range of prospects for progress.

Man-made cotton is viscose fiber, a major variety of man-made fibers. By the natural cellulose alkali alkali cellulose, and then and the role of carbon disulfide to generate cellulose xanthate, dissolved in dilute alkali solution to get a viscous solution called viscose, viscose by wet spinning and a series of processing processes that become viscose fiber. Its basic composition is cellulose (C6H10O5)n o general viscose fiber cross-section is serrated skin-core structure, longitudinal straight with grooves across. While the rich fiber without the core structure, the cross-section is round.

Viscose fiber has good moisture absorption, in general atmospheric conditions, the moisture return rate of about 13%. Significant expansion after moisture absorption, diameter increase of up to 50%, so the fabric after the water feel stiff, shrinkage rate.

General viscose fiber breaking strength than cotton is small, about 1.6 ~ 2.7cN / dtex; elongation at break is greater than cotton, 16% ~ 22%; wet strength decline more, about 50% of the dry strength, wet state elongation increased by about 50%. Its modulus is lower than cotton, simple deformation under a small load, and poor elastic recovery performance, so the fabric is simple elongation, poor dimensional stability. The strength of rich fiber is very high than the general viscose wet strength, elongation at break is smaller, good dimensional stability. General viscose wear resistance is poor, while rich fiber is improved.

The chemical composition of viscose fiber and cotton is similar, so more alkali resistance and not acid resistance, but alkali resistance and acid resistance are worse than cotton. Rich fiber has good alkali resistance and acid resistance. The same viscose fiber coloring and cotton similar, color chromatography, coloring performance is good. In addition, the thermal properties of viscose fiber is also similar to cotton, density close to cotton for 1.50 ~ 1.52g/cm3.

General viscose fiber moisture absorption is good, easy to color, not easy to static electricity, have good spinning performance. Short fiber can be pure spinning, and other fabric fiber blend chemical fiber fabric, fabric soft, complete smooth, breathable, comfortable to wear, bright color, dyeing fastness is good. Suitable for making underwear, outerwear and various decorative items. Filament fabric is light and thin, in addition to being used as clothing can also be woven quilt and decorative fabrics. The disadvantage of this type of viscose fiber is poor fastness, low wet modulus, high shrinkage and simple deformation, elasticity and wear resistance is poor.

As cotton and modal are recycled fibers, electrostatic reaction transactions occur, severe electrostatic plus friction will produce open fire, autumn and winter, fabric electrostatic reaction also transactions caused by fabric pilling and pilling. Now more and more businesses in the late addition of anti-static finishing of the fiber. This can improve the wearing comfort of the fabric, but also to prevent fabric pilling, improve the feel and fabric beauty. For example, ZJ-Z09H non-ionic antistatic agent, can be highly effective in improving the moisture absorption and electrical conductivity of the fabric, and decontamination and dust resistance, and at the same time can improve the fabric anti-pilling more than 0.5 level.

Contact: Jeanne yang(MISS)

Phone: 13912652341

E-mail: [email protected]

Add: Room A2216/A2217,Double-Star Building,No 567 New South Middle Road, KunShan City JiangSu Province ,China.