Case one

In July 2002, the centrifuge (closed) in the second workshop of a factory in Jiangyan, Jiangsu Province, suddenly exploded when it just started to unload the W-100-1 fabric with antioxidant and toluene solvent respectively from the enamel counter kettle, resulting in the death of one employee and serious injury to one employee. The material was mechanically stirred in the reaction kettle for more than 20 hours, which accumulated electrostatic charge. As the kettle is enamel reactor, the accumulated static electricity can not be grounded through the reactor grounding wire, the material contains high level of static electricity.

Case 2

In December 2002, in a factory slurry workshop in Danyang, Jiangsu Province, workers used a vacuum pump to suck vinyl acetate to the reaction kettle, about 30kg left in the barrel, when an explosion suddenly occurred. The workers put out the fire by themselves and 1 worker was burned. The cause of this explosion is: vinyl acetate material in the rapid flow through the plastic pipe electrostatic buildup, when the plastic pipe contact with the zero potential barrel, the formation of high bottom pressure potential difference discharge, spark detonation of vinyl acetate vapor in the air

Case three

In late spring 2005, an enterprise sampling personnel in the light oil tank top sampling occurred in a minor flash fire accident. The accident did not cause casualties and other equipment damage, but illustrated the serious accident potential in the sampling process.

Case 4

At 14:45 on October 31, 2000, a female worker from a machine repair workshop of a petrochemical plant in Henan Province carried a square iron barrel with a plastic handle hook to the II catalytic crude gasoline valve sampling port of the third refinery, intending to put some gasoline for cleaning tools during the maintenance of the acid pump. When the female worker hung the barrel on the sampling valve and opened the hand valve to release the oil, the barrel caught fire. This is a typical accident caused by the valve opening too much, the gasoline flow rate is too fast and lead to the accumulation of electrostatic charge, resulting in spark discharge.

Case 5

In January 2004, a motorcyclist went to the gas station to refuel, parked his car next to the metering machine, turned off the engine, and used the engine key to open the gas tank cover waiting for refueling. The gas station staff put the synthetic resin material tank cover on the cement protection table next to the tank, did not wear gloves, directly holding the gun handle with his hand, the spray gun mouth close to the motorcycle fuel tank refueling port, began to refuel when the fire suddenly emerged from the fuel tank refueling port.

Case six

On July 17, 2007, an explosion occurred at the Barton Solvent Plant in Kansas, USA, and caused a fire that destroyed the entire tank farm. More than 40 storage tanks ranging in size from 3,000 to 20,000 gallons were ignited in the fire, and the accident resulted in 11 residents and firefighters receiving medical treatment. The Barton solvent plant was shut down. The explosion threw the tops of the storage tanks into the air, blowing them 130 feet away and, moments later, damaging two more storage tanks, causing components to leak from those tanks. As the fire spread, components from nearby tanks were released and ignited, and some debris splattered and struck a mobile home and adjacent store. The accident caused the evacuation of 6,000 residents. Smoke from the explosion billowed more than 200 feet into the air and could be seen for miles. According to the analysis: the accident was caused by electrostatic sparks, the generation of static electricity is mainly due to naphtha in passing through the pipeline, pump electrostatic, at the same time, the oil in the process of pumping liquid from the tanker truck to the storage tank, due to the entry of air, resulting in foam and turbulence, intensified the generation of oil electrostatic

Case 7

On November 30, 1987, Yanshan Petrochemical Company refinery oil loading table in to Sanhe County, Hebei Province, Tuzhuang Township gas station Dongfeng 140 type car tanker loaded 0 diesel fuel, tanker suddenly exploded and caught fire. The explosion gas wave lifted the driver who was watching the oil level on the top of the tanker to the ground, his face and hands were burned, and the storage tank of 6 station cubic meters was deformed by the explosion and scrapped with seven ruptures.

Case eight

May 27, 1995, a southern shipping company "A port 5" in a port loading 219 barrels of mixed benzene and 35 tons of polyoxyethylene, due to the mixed benzene outside the main deck channel sealing situation is not good, a small amount of benzene vapor overflow. The volatile benzene vapor was denser than air, so it settled at the dead end of the ship's bow and the gap between the benzene barrels. During the operation, the friction between the barrel and the ship wall produced static spark, causing the benzene vapor to burst into flames.

Case 9

June 4, 1997, Guangzhou Shipping Group Company "Daqing 203" ship in a certain oil transportation anchorage barging operations. Due to the cabin static electricity caused by oil and gas explosion, "Daqing 203" and three overloaded oil barges exploded and caught fire one after another. The leaked crude oil formed a flowing fire of more than 10,000 square meters on the river surface. The fire caused 9 deaths and direct economic losses of tens of millions of RMB.

Case 10

On April 30, 2006, a tanker car of an oil transportation company was filling E10 No. 90 ethanol gasoline with a crane tube at an oil depot when the filling port of the tanker car suddenly caught fire. The filler and the driver of the tanker quickly extinguished the fire with asbestos placed near the filling port and in the room of the microcomputer control monitor, without causing any damage. Cause of the accident: This is a fire accident caused by the accumulation of electrostatic charges.

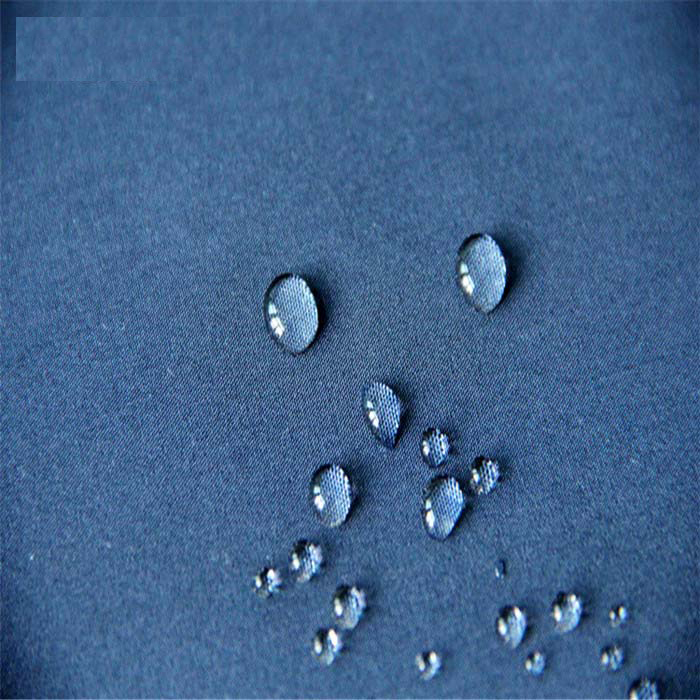

Static electricity caused by the accident is endless, through the above cases we can clearly understand that the insignificant electrostatic once the damage caused, will cause incalculable losses, light economic losses, heavy casualties. So how to pre-static from the root cause is the urgent issue at hand. Carefully watch the above cases, you can find that most of the static electricity from the human body carries static electricity, thus causing harm, so now the mainstream measures to static electricity is to require employees to wear work clothes with static performance, the production of such protective clothing is the first choice is to remove static fabric.

What is a de-static fabric? From the weaving of the fabric can be divided into two forms, one is in the general fabric on the antistatic agent treatment, so that the fabric has antistatic properties. It is usually called the post-finishing fabric. The other is the adoption of new conductive fiber and cotton fiber through advanced spinning equipment and weaving technology, and after printing and dyeing treatment, divided into cotton, polyester-cotton, chemical fiber three categories. The fabric has good durability de-static function, while having the performance of dustproof, washable, dry cleaning, etc.

The progress of industry can not be separated from the safety and security, only to ensure the safety of production, in order to manufacture value. Therefore, it is strongly requested that major related enterprises and factories require employees to wear de-static workwear. To escort the progress of production.

Technology Co., Ltd - a professional integrated service provider for the supply and application of functional fabrics. The company has strong scientific and technological research and development strength, advanced production and inspection means, and has the right of self-supporting import and export. It is also an ISO9001-2008 and ISO4001-2004 certified enterprise. The main products are: de-static series, high temperature resistant fireproof series, fireproof series, oil and water resistant series, acid and alkali resistant series, general workwear fabrics and auxiliary materials, etc.. Involved in metallurgy, fire fighting, petroleum, chemical, machinery, medical and other industries. Decades of dedication, market-oriented, innovation as the driving force, quality for survival, has progressed to grow. Technology to provide you with a full range of solutions and perfect products and services.

Contact: Jeanne yang(MISS)

Phone: 13912652341

E-mail: [email protected]

Add: Room A2216/A2217,Double-Star Building,No 567 New South Middle Road, KunShan City JiangSu Province ,China.