I. Parallel laminated fibers

The spinning of parallel laminated fibers is more difficult than the spinning of skin-core fibers, so the requirements for the polymer are higher.

(1) The two polymer materials used for spinning parallel laminated fibers should have good compatibility, otherwise they are easy to peel off during the spinning process, making it difficult to carry out the spinning process.

(2) the two polymer materials used in the corresponding spinning process conditions should have a similar melt viscosity, in order to avoid the melt in the spinning process from the spinneret spitting out the "bend" phenomenon, affecting the normal spinning process.

The main factors affecting the viscosity of the melt of the two polymer materials under the conditions of the spinning process include:

(1) the relative molecular mass of the two polymer materials.

(2) The melt temperature manipulation of the two polymers in the respective screw extruder, bending tube and the temperature manipulation of the final spinning chamber.

(3) The dependence of the viscosity of the two polymer melts on the shear rate, including the pump supply of each of the two polymer melts, the aperture and length-to-diameter ratio of the spinnerets, etc.

Therefore, before the spinning work of the parallel-type laminated fiber is carried out, it is necessary to do all kinds of necessary and corresponding intention work. In doing so, it also helps to analyze the possible problems.

Second, multi-layer parallel laminated fiber

Multilayer parallel laminated fiber is the result of parallel fiber lamination and then lamination, which is made of two polymer materials with certain compatibility alternately arranged into a multilayer structure, and laminated along the fiber axis. The two polymer materials should be selected to ensure that the spinning process is not easy to peel, but also to consider the final peelability of the manufactured fiber.

The peeled microfiber has a rectangular shape with four angles, which is suitable for wiping cloth. The fibers with rectangular cross-section have different dimensions in the length and width directions, and the ease of bending and deformation of the fibers is related to the aspect ratio of the fiber cross-section, so the fabrics obtained from different aspect ratios of fibers will produce different styles. If the width of the rectangle direction is small to a certain extent, but also due to the effect of the end of reflection similar to the colorful butterfly wings.

Third, the orange petal type laminated fiber

Orange petal type laminated fiber is composed of two polymers with different chemical structure and / or properties of a lobe type laminated fiber, its cross-section consists of similar "orange petal" shape of the lobes. For example, the polymer raw material used can be PET and PA6. There is a definite compatibility between the two to ensure proper spinning and finishing processes, but there is a difference in properties to achieve a peeling effect during the fabric treatment.

The adoption of this form of fiber cross-section, after stripping can be obtained "wedge" type microfiber, each single fiber has three sharp corners, used as a wipe cloth is particularly beneficial. This orange petal type laminated fiber can be divided into 6 + 6 or 8 + 8 and other types, that is, from 6 (or 8) PET and 6 (or 8) PA6 petals spaced from each other to form the orange petal type. Usually the proportion of PET is increased. If the two components are not peeled well, simply cause the microfiber fabric on the poor color. To solve this problem, can also be made into EHDPET/PA6 (20/80) orange petal type laminated fiber, and then the laminated fiber fabric for hydrolysis, after dissolving EHDPET to get PA6 single-component microfiber. Adopting the spinning method of orange petal type laminated fiber, we can finally obtain the ultra-fine fiber with a linear density of about O. 15dtex.

Fourth, the hollow orange petal type and beige type laminated fiber

Hollow orange petal type laminated fiber is an improvement of the above orange petal type laminated fiber, the purpose is to improve the peeling effect. As the orange petal type laminated fiber flaps are connected to each other, sometimes peel bad. If the middle part of the fiber into a hollow, you can reduce the contact area between the orange flap, conducive to peeling.

Beige laminated fiber is a kind of lobe laminated fiber composed of two polymers with different chemical structures and/or properties, whose cross section consists of a "beige" skeleton and a fan between the "beige" skeleton. One of the polymers (e.g. PA6 or PET) is made into a "meter" shaped skeleton and the other polymer (e.g. PET or PA6) is the sector between the "meter" shaped skeleton. PA6 is usually adopted as the "meter" shaped skeleton. As the proportion of the "m" skeleton increases, the "m" skeleton gradually becomes thicker. If the proportion of "m" skeleton is less than 15%, the skeleton is too thin and uneven, which will increase the difficulty of peeling and affect the effect of peeling. And the proportion of "m" skeleton is too high (such as up to 50%), the skeleton becomes very thick, after stripping will form a thicker fiber, affecting the softness of microfiber fabrics, but also increase production costs. Therefore, the proportion of "beige" skeleton is more appropriate to choose 20%. The characteristics of the fabric made of this beige laminated fiber is that both the softness of the fan-shaped microfiber and the rigidity and stiffness of the "beige" skeleton material.

There is another adoption of EHDPET as the "rice" frame material laminated fiber, with the fiber woven into the fabric, the EHDPET with dilute alkali solution hydrolysis dissolved, the final fan-shaped microfiber fabric. The meter-shaped laminated fiber is often referred to as "8+1" type, i.e., it is composed of 8 fan shapes plus 1 meter shape. In order to make the single fiber thread density finer, can also be made into "16 +1" and other varieties. In order to ensure a good balance between the spinning process and the easy peelability of the single fiber in the finishing process, the two polymer components selected should have the appropriate compatibility.

V. Gear-type laminated fibers

Gear-type laminated fiber is actually a variant of the beige laminated fiber. It is also composed of two polymers with different chemical structures and/or properties and has a gear-shaped cross-section: one polymer forms the body of the gear and the other forms the gap material between the teeth.

After the gear-shaped laminated fibers are peeled, the material in the gap between the teeth forms microfibers that provide a soft style to the fabric, while the material forming the body of the gear provides rigidity and stiffness to the fabric. In fact, the gear-shaped laminated fiber can be considered as a modification of the beige laminated fiber. The same principle as the selection of two polymer components for beige laminated fibers, the two polymer components for geared laminated fibers should also have suitable compatibility.

Sixth, the core type laminated fiber

Skin-core type fibers are made of two component layers wrapped around each other, and laminated along the fiber axially. Usually refers to the same core type, in addition to eccentric type, shaped core type and multi-layer core type. The skin-core type fiber is mostly used for self-adhesive fiber, for example, the ES fiber developed by Japan Choshu is a skin-core type fiber with low melting point PE (tm = 107℃ ) as the skin layer and high melting point PP (tm = 167℃) as the core layer. The fiber and other fibers are uniformly blended to make a nonwoven fabric, and then hot air or hot rollers are pressed together at a temperature between the melting points of PE and PP to melt the skin component, and hot melt bonding occurs between ES fibers or between ES fibers and other fibers. Since the fiber skin layer is very thin, the bonding between the fibers is delicate and the product feels soft, and the strength of the nonwoven is improved. Chen Guokang et al. reported a method of manufacturing laminated fibers with PE or its copolymer as the skin layer and PP as the core layer, claiming that the softness of the fibers can be improved.

There are also reports of skin-core type fiber manufacturing with PA6 as the skin layer and PET as the core layer. The fiber is used in the manufacture of tire cord, which can make full use of the excellent adhesion between PA6 and rubber, and can play the rigidity and high modulus of PET, thus improving the "flat spot effect" of tires. In addition, there is a skin-core type fiber with PA6 as the skin and PET as the core. When manufacturing the fiber, the appropriate increase in the proportion of PET can reduce production costs, while improving the modulus of the laminated fiber; PA6 for the skin can also improve the fiber coloring, abrasion resistance and moisture absorption properties. In recent years, some manufacturers adopt recycled PET as the core layer to produce leather core type fiber, which not only further reduces the cost of the product, and the recycling of waste materials, utilization, and environmental protection has a positive significance.

If the core layer adopts a good moisture-absorbing polymer materials or materials with conductive properties, it can improve the moisture-absorbing or conductive properties of the fiber. The authors have PET, PA6 or PP as the skin layer, with a homemade co-polyether ester as the core layer prepared with excellent antistatic properties of the core type fibers, the resulting fibers after removing the oil agent specific resistance value of 1x10 of 7 Ω? cm. also have a conductive polymer containing components as the core layer, the manufacture of conductive core type laminated fibers reported.

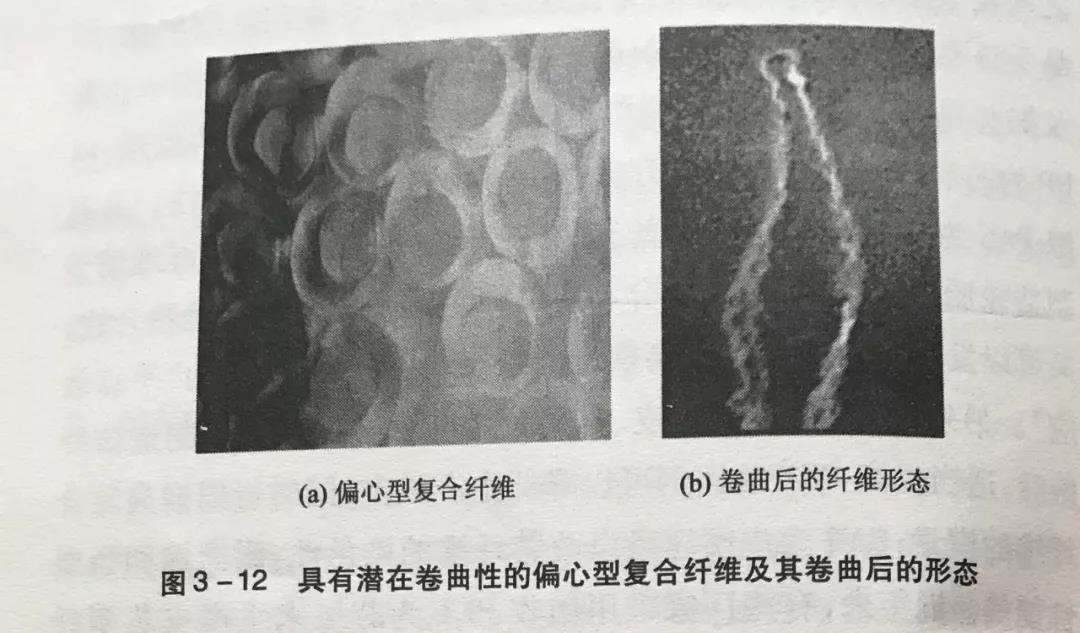

Positive skin core type laminated fiber spinning, although the requirements for spinning performance than the parallel type laminated fiber slightly lower, but the melting point of the two polymer components should not be too much difference, and the two components in the spinning process conditions of the melt viscosity should be complete may be similar, and have good compatibility, that is, the fiber can be well bonded together, not in the skin layer and core layer between the obvious boundary. Spinning eccentric laminated fiber, the requirements of the spinning performance is slightly higher, mainly requires two components in the spinning conditions of the melt viscosity is similar, in order to avoid the melt from the spinneret hole extrusion when the "bend" phenomenon. If designed to two chemical structure and / or different properties of the polymer composition of the bi-psychological laminated fiber (Figure 3-12), but also to give the fiber three-dimensional station body spiral permanent curl properties.

Seven, the sea an island type laminated fiber

Sea an island type laminated fiber is actually a multi-core type skin core laminated fiber, composed of a polymer material core component (also known as "island" phase or dispersed phase) in the form of longitudinal continuous dispersion in another polymer material composed of sea component (also known as "sea" phase Some people call it polymer ligand fiber, and some people call it sea-island type laminated fiber. Usually, the two polymers used to make sea-island laminated fibers must have selective solubilization properties for certain solvents.

For example, when the material of the island component is selected as PET, PA6 or PA66, PS or PE can be adopted as the sea component, so that when spinning into sea-island laminated fiber, PS or PE can be dissolved by toluene or xylene to obtain PET, PA6 or PA66 superfine fiber. If the sea component is replaced by the easily hydrolyzed polyester EHDPET, the sea component can be removed with dilute alkali solution to obtain the same ultra-fine fiber. Sea-island laminated fiber can be used not only to prepare microfiber, can also be used to prepare porous hollow fiber: the above sea and island components are switched, such as PET, PA6 or PA66 as the sea component, and EHDPET as the island component, the resulting sea-island laminated fiber by alkali hydrolysis, the resulting porous hollow fiber.

The microfiber filaments can be used as raw material for peachskin or suede, while the microfiber staple can be used to make artificial suede. The porous hollow fiber is usually used to make artificial leather, which is soft, warm and elastic, and is a good material for finishing various footwear and trolley bags.

The above adoption of PS or PE as a sea component, the use of sea an island type laminate spinning a melting stripping method of manufacturing microfiber technology, due to the need to use organic solvents in the stripping process, is now on the verge of elimination. Instead of the sea an island type laminated spinning - hydrolysis stripping method technology, that is, the aforementioned PET, PA6 or PA66 as the island phase components, easy hydrolysis polyester EHDPET as the sea phase components of the spinning of sea an island type laminated fiber technology. In fact, the key to this technology is the design and manufacture of sea-island laminated spinning components, as well as the synthesis and performance manipulation of easily hydrolyzed polyester EHDPET.

Eight, other types of laminated fibers

In addition to the above-mentioned laminating fibers, there are many kinds of extraordinary shapes, extraordinary performance of laminating fibers. For example, in the triangle fiber at the three sharp corners of the inlay easy hydrolysis of small triangle, hydrolysis will be in the three sharp corners of the formation of small grooves, so that the fiber to produce "silk" effect.

In the middle of PA6 finished fiber with circular cross-section, a polygonal polymer material with high TiO2 content is embedded as the core layer, and each sharp corner of the polygonal shape is connected to the outer edge of the fiber, resulting in a skin-core type laminated fiber with very high core shape and performance. No matter the finish line is directed at the fiber from any angle, it is only reflected and does not pass through the fiber. The knitted fabric of this fiber is very popular for making swimwear, which is white and opaque. If it is made of summer workwear, it is draped and flowing, sprinkling, showing elegant style, very suitable for women's clothing.

Contact: Jeanne yang(MISS)

Phone: 13912652341

E-mail: [email protected]

Add: Room A2216/A2217,Double-Star Building,No 567 New South Middle Road, KunShan City JiangSu Province ,China.