Intelligent composting and fermentation technology system assisted by nano membrane composite fabric and nano fiber composite fabric

The nano membrane intelligent composting and fermentation technology system can provide corresponding solutions according to the total fecal sewage volume of the project county, plan the fecal sewage treatment center, arrange it in a decentralized manner, conduct centralized treatment, share and use it, reduce transportation costs, and solve the problem of environmental odor.

Chinese name: nano membrane intelligent composting technology

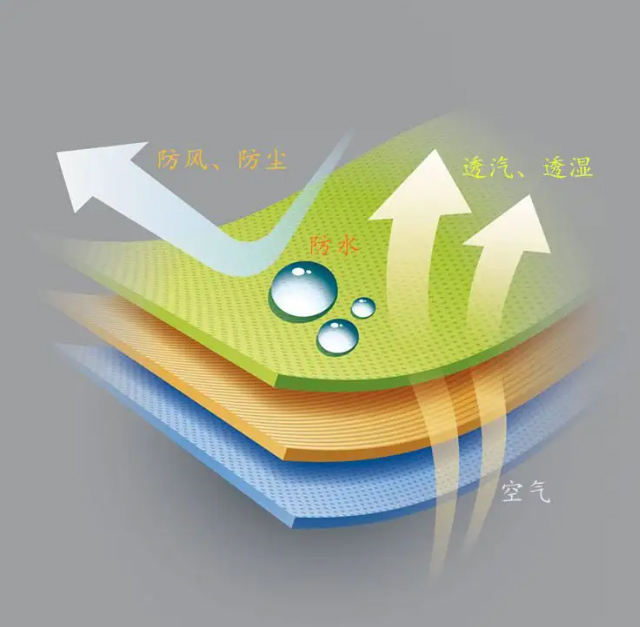

Features: waterproof, little impact on the surrounding environment, no odor overflow, etc

Material: nano membrane composite fabric

Technical characteristics

Nanofilm intelligent composting does not need to build workshops and sheds, but only needs to harden the site. It can be compatible with the existing infrastructure of current mainstream trough and strip composting, and the service life of the equipment can be as long as 8-10 years; Environmentally friendly and odorless. The nano membrane is a polymer selective breathable membrane, which has the functions of waterproof, moisture permeability, sterilization, deodorization, etc. It has little impact on the surrounding environment, no odor overflow, and does not need to carry odor collection and treatment equipment; Wide range of adaptation.

There are two traditional composting methods for nano membrane composting:

Anaerobic Composting:

A composting process in which anaerobic microorganisms are mainly used under anoxic or anaerobic conditions. In addition to humic organics, carbon dioxide and methane, the final product also contains ammonia, hydrogen sulfide and other organic acids and other reducing substances. The process is simple, without ventilation, but the reaction rate is slow, and the composting cycle is long.

Aerobic composting:

Under the condition of manual control and certain carbon nitrogen ratio (C/N), moisture, temperature and ventilation, the process of microbial transformation of organic matter into stable humus, such compost products after fermentation are odorless and fly free, but have a light soil flavor.

As a new way of composting, nano film composting has appeared in the view of the majority of users. This method combines the advantages of the above three composting methods, reduces their disadvantages, and brings users a new choice of composting fermentation.

As the nano membrane compost uses new membrane materials for covering fermentation, it can be fermented in the open air, and the membrane materials have unidirectional permeability, which can effectively isolate odor and external water molecules, but the internal water vapor can pass through normally to better ensure the internal fermentation state. In addition, the NCS intelligent molecular membrane composting fermentation system under CNOOC Environment can customize special membrane materials according to the climate of different regions, so that the fermentation products under different climate and humidity can obtain a good fermentation environment under the cover of membrane materials.

As the fermentation of nano membrane compost only requires air supply system, membrane covering fermentation system and intelligent control system, the investment cost only requires 30% of the fermentation of other reactors, which greatly reduces the investment cost and low operating cost. Compared with the traditional operating cost, the operation of nano membrane fermentation has reduced by 90% in terms of fame, and completely realizes the unattended function, allowing you to control the fermentation without leaving home.

R&D focus

For the development and test of auxiliary equipment at the front and rear end of nano membrane intelligent composting, the focus of optimization is to establish a system solution with nano membrane as the core process.

Market application

At present, the market promotion of nano membrane intelligent composting technology has achieved certain results, and more than 30 demonstration bases have been established in Shandong, Hebei, Jiangsu, Inner Mongolia, Hubei and other places.

The Internet of Things system is added to the intelligent nano membrane composting technology. The APP downloaded from the park can monitor the humidity, temperature and oxygen content in the intelligent nano membrane in real time, and regulate them according to the data.

The reading hints that the pollution of livestock and poultry breeding is the focus of the current society. The State encourages the selection of an economical and applicable treatment mode according to the characteristics of resources and environment in different regions. For the farms with different breeding varieties and scales, how to choose the appropriate livestock and poultry manure treatment mode is still a problem faced by many farms. In response to this problem, the reporter interviewed Ma Ruiqiang, a doctor of microbiology and senior agronomist of China Agricultural University, a postdoctoral fellow of the Institute of Agricultural Environment and Sustainable Development of the Chinese Academy of Agricultural Sciences, and the general manager of Zhongnongchuangda (Beijing) Environmental Protection Technology Co., Ltd., to analyze the advantages and disadvantages of various animal manure treatment models, and emphatically introduced how the nano membrane intelligent composting technology works.

Reporter: What are the characteristics of the feces of pigs, cattle, chickens and other livestock and poultry, and what are the differences in the treatment methods of chicken feces?

Ma Ruiqiang: Both pigs and cows are blistered dung. The treatment feature is that the dung water needs to be treated. After the dry wet separator, the solid dung can be made into organic fertilizer. The liquid can only be returned to the field after multistage oxidation. Chicken manure is mainly fresh manure with a moisture content of 80%. The digestive tract of chicken is short, and 70% of the feed protein can not be digested, but eventually these proteins are decomposed into ammonia, which is very strong, making chicken manure very smelly. However, chicken manure does not need to go through a dry and wet separator, and can be directly added to ferment into organic fertilizer, which can solve the odor problem of chicken manure and produce organic fertilizer.

It is precisely because the digestive tract of chicken is short and many nutrients are not absorbed, so chicken manure has good fertilizer effect. The content of nitrogen, phosphorus, zinc and copper is significantly higher than cow manure and sheep manure, while the content of potassium is equivalent. If processed and utilized well, it is a good organic fertilizer. But now many farmers directly pull uncooked and fermented chicken manure and dried chicken manure onto the ground, sometimes burning seedlings and cores, and sometimes soil hardening occurs, which is very harmful to agricultural production. Therefore, popularizing the knowledge of manure fermentation organic fertilizer and promoting low-cost treatment mode will greatly benefit the development of planting and breeding industries.

Reporter: At present, what are the main ways to deal with chicken manure in chicken farms in China? What are their characteristics, advantages and disadvantages?

Ma Ruiqiang: China's traditional and mainstream composting modes mainly include tank composting, strip composting and reactor composting. The trough type compost and the strip type compost belong to the open type compost, which has large processing capacity but serious environmental pollution; The reactor compost has good airtightness and strong environmental protection performance, but the treatment capacity is limited and the control cost is high. The film covered aerobic composting technology is a new, efficient and environmentally friendly composting technology. It not only has the advantages of good reactor composting airtightness, strong environmental protection performance, and large processing capacity of trough type and strip type composting, but also is well compatible with the existing infrastructure models of current mainstream trough type and strip type composting. Even if a new site is built, it only needs a hardened site, and does not need to re build the infrastructure.

Reporter: For the resource utilization of chicken manure, what are the new technology applications of the membrane covered aerobic composting technology you mentioned?

Ma Ruiqiang: At present, domestic chicken farms are scattered, small in scale, and distributed among villages. Compared with other types of farms, chicken farms are small in size. The environmental pressure caused by the stench of chicken manure is a headache for chicken farms. The nano membrane intelligent composting technology should be the most promising and suitable model for the resource utilization of chicken manure.

Nanomembrane composting is a composting method without turning over, which can save a lot of labor and energy during operation. After being covered by the membrane, the aeration at the bottom can provide enough oxygen for the microorganisms in the pile to ferment. With the rise of temperature, the macromolecules of ammonia, hydrogen sulfide and other odors overflow, and the microporous structure of the nano membrane can block the entry of water outside, but can pass through the small molecules of water, At the same time, ammonia and hydrogen sulfide macromolecules cannot pass through, and the water vapor dissolved in the membrane surface finally returns to the pile body and is used by microorganisms, so as to achieve the effect of not only removing water but also having no odor. The decomposed farm manure is produced, which can be directly returned to the field or sold to the organic fertilizer factory for processing and production of commercial organic fertilizer.

At present, the market promotion of nano membrane intelligent composting technology has achieved certain results, and more than 30 demonstration bases have been established in Shandong, Hebei, Jiangsu, Inner Mongolia, Hubei and other places. For example, a local farm in Shouguang, Shandong Province, uses nano film composting equipment to produce organic fertilizer with good quality and effect, which is popular with local vegetable growers and sells for 600-800 yuan per ton.

To sum up, its technical and technological advantages are as follows:

Less investment. Nanofilm intelligent composting does not need to build workshops and sheds, but only needs to harden the site. It can be compatible with the existing infrastructure of current mainstream trough and strip composting, and the service life of the equipment can be as long as 8-10 years; Environmentally friendly and odorless. The nano membrane is a polymer selective breathable membrane, which has the functions of waterproof, moisture permeability, sterilization, deodorization, etc. It has little impact on the surrounding environment, no odor overflow, and does not need to carry odor collection and treatment equipment; Wide range of adaptation. It can be effectively treated in large and small scale, and is applicable to large-scale breeding farms, breeding communities or centralized treatment centers in areas with temperatures above - 30 ℃; Low operation cost. The whole process of fermenting 1 ton of organic fertilizer requires only 2 kilowatt hours of electricity, and the total cost of 1 ton is less than 20 yuan. 1500 tons can be produced throughout the year; Save time and labor. Modular design, flexible and movable, installation can be completed within 1 week, and it only needs to be flipped once when building the pile, without frequent flipping. And it is easy to operate. The remote intelligent control of Internet of Things devices is connected through sensors, and 24-hour monitoring can be conducted on mobile phones or computers; Composting efficiency is high. The dung will be fermented into organic fertilizer in 15-20 days, and cow dung will be converted into cow mattress in 7-10 days.

Reporter: What is the focus of the next improvement and optimization of this technology?

Ma Ruiqiang: At present, this technology is at a mature stage. In addition to the treatment of chicken manure, it also has a very good effect on the harmless treatment and resource utilization of cattle manure, sheep manure, pig manure and other livestock manure, as well as branches, straws, drug residues, urban sludge, tail vegetables and other organic wastes.

In the next step, the focus of this technology research and development is the development and test of auxiliary equipment at the front and rear end of nano membrane intelligent composting, and the focus of optimization is to establish a system solution with nano membrane as the core process.

A7.jpg

With the national emphasis on environmental protection in the process of solid waste treatment, reducing greenhouse gas and odor emissions will become the top priority to measure the practicality and popularization of related technologies. Membrane covered aerobic composting technology, due to its core nano membrane structure, can significantly reduce the emission of CH4, N2O, NH3 and other odors in the process of waste treatment, achieve environmental compliance, and will be vigorously promoted and applied in the waste treatment industry.

According to the Work Plan for Promoting the Resource Utilization of Livestock and Poultry Manure in the Whole County (2018-2020), this year is the end of the project. The comprehensive utilization rate of livestock and poultry manure in the project county should reach more than 90%, and the supporting rate of fecal treatment facilities and equipment for large-scale breeding farms should reach 100%. The nano membrane intelligent composting mode can provide corresponding solutions according to the total fecal sewage volume of the project county, plan the fecal sewage treatment center, arrange it in a decentralized manner, conduct centralized treatment, share and use it, reduce transportation costs, and solve the problem of environmental odor.

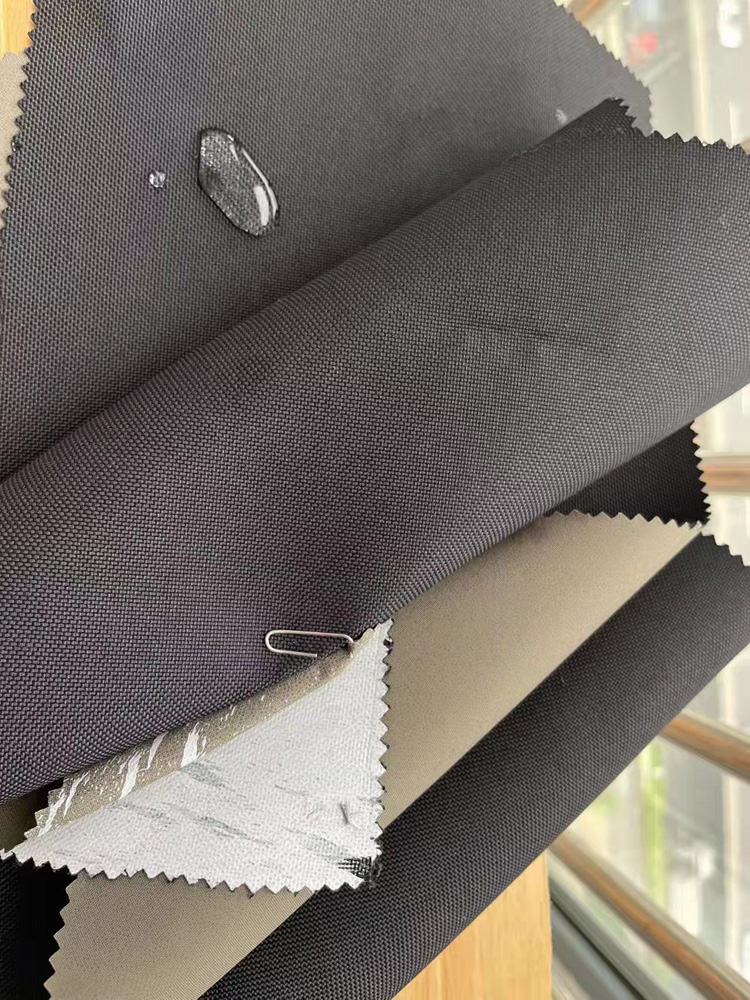

Knowledge of nano membrane composite fabric:

brand

Yingjie Textile

Article No

YJ02

Product name

Nano membrane composite fabric

Fabric variety

reunite with

Color characteristics

custom color

purpose

Clothing and industrial fabrics

width of cloth

148cm

Yarn count

40s

Quality standards

Row mark

style

modern

Processing customization

no

Imported or not

no

Gram weight

300-500g/㎡

Packing specification

Full roll packaging

Contact: Jeanne yang(MISS)

Phone: 13912652341

E-mail: [email protected]

Add: Room A2216/A2217,Double-Star Building,No 567 New South Middle Road, KunShan City JiangSu Province ,China.