In the past decade, the functional textile market has developed rapidly, and various functional fabrics with unique selling points have emerged one after another. In addition to meeting the basic functions of concealing ugliness and beautifying the market, textiles, especially functional textiles, are constantly expanding more functional added value. For example: waterproof fabric, flame retardant fabric, antibacterial fabric, fragrance fabric, mosquito resistant fabric, heat storage and thermal insulation fabric, etc. It can be used not only in various general consumption fields, but also in various industries such as life, industry, medical treatment, military, transportation, etc. The market potential is huge.

In many functions of textile fabrics, many functions need to be processed separately, and it is very likely that more than two functional additives will cause many defects and problems due to compatibility and physical and chemical properties when used at the same time. Common defects include: sedimentation, oil floating, delamination, blistering, incompatibility, spots, splash, sediment and other conflicts. But at the same time, due to the improvement of environmental protection and energy saving threshold, multi additives processing in the same bath is a major trend in the future. One bath finishing with multiple auxiliaries can greatly save the production cost and time cost of printing and dyeing enterprises. In this issue, we mainly screen and analyze the application cases of "waterproof+flame retardant" two in one finishing.

It is not difficult to make waterproof or flame-retardant products alone. Select appropriate products and produce according to the dip rolling process. However, the process of waterproof and flame retardant is not simple. First of all, not all waterproof agents and flame retardants are suitable for two in one processing. Select products with the same ionic property, and test the stability of each single item and the solubility of two in one. Secondly, the "degree" between the effects of waterproof and flame retardant should be balanced according to the different use amount of well compatible waterproof agent and flame retardant. The waterproof should meet the requirements, and the flame retardant should also meet the requirements. Let's take a look at the specific practices of waterproof 100 points+flame retardant B1 process before washing:

Detailed steps:

1. Weighing and blending

1.1 Cloth for cutting experiment 300 × 21cm size, spare

1.2 Take a beaker to the electronic scale and clear it to zero. Weigh the flame retardant FUNCTEX F-4870 4g (converted according to the dosage), pour it into the beaker, add a small amount of water and stir it evenly;

1.3 Weigh 20g of ANFONE RH-4869 (converted according to the dosage), pour it into a beaker, add water to 200g, and stir it evenly for standby.

1.4 Specific formula:

4g flame retardant FUNCTEX F-4870

20g three proofing finishing agent ANFONE RH-4869

176g water

————————————————————

200g in total

2. Dip rolling process

One dipping and one rolling, the liquid carrying rate is 80%

3. Drying

Put it into the oven at 170 ℃ × 1 minute

4. Testing

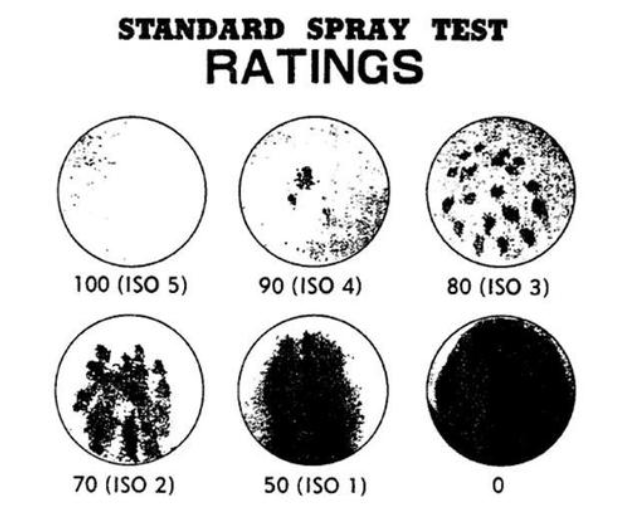

4.1 The waterproof test shall be carried out according to the steps of AATCC22-2005 Textile Water Repellency Test Spray Method, and the samples shall be taken for comparison, as shown in the following figure:

4.1.1 Waterproof evaluation standard: refer to AATCC 22 Water Level Chart (Table 1 below) to evaluate the waterproof performance

640 (6).png

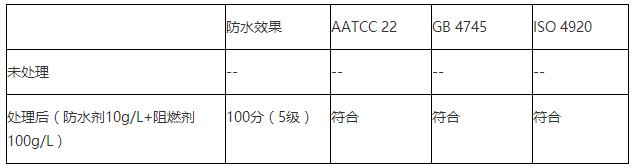

4.1.2 Evaluation of waterproof effect:

640 (2).png

4.2 Flame retardant test shall be conducted according to the steps of GB/T 5455-2014 Textiles Flammability Determination of Damage Length, Smoldering and Continuous Burning Time in Vertical Direction, as shown in the following figure: 4.2.1 Flame retardant evaluation standard: refer to GB/T 5455-2014 "Determination of Flame Retardancy of Textiles"? Performance evaluation of 17591-2006 Flame Retardant Fabrics (see Table 2 below)

dsadfe.jpg

4.2.2 Flame retardant effect evaluation:

Conclusion: Through the above double effect composite finishing of waterproof and flame retardant, the textile fabric has both waterproof (100 points) and flame retardant (B1 level) effects, and the cost of these two additives is much lower than that of single waterproof additive and single flame retardant additive, which is in line with the environmental protection program of energy conservation, consumption reduction and clean production. At present, the multi in one composite finishing has received more and more attention from smoldering processing enterprises and fabric developers. It is of great practical significance in the printing and dyeing industry to finish two kinds of functional finishing in one processing.

Contact: Jeanne yang(MISS)

Phone: 13912652341

E-mail: [email protected]

Add: Room A2216/A2217,Double-Star Building,No 567 New South Middle Road, KunShan City JiangSu Province ,China.