Pilling

Knitted fabrics pile grinding is a post-finishing finishing method, pile class fabrics are cotton terry, cotton terry cloth, T / C terry cloth and terry cloth, CVC terry, etc..

Customary distinction method is: terry cloth terry small, terry cloth circle large. This type of terry structure fabric pile is the use of steel needle roller, mechanical cut terry structure, produce lint. Abrasive fabric weaving structure is more, they are the use of abrasive machine carbon fiber and sandpaper mechanical friction to make the surface of the fabric to produce uniform short pile.

Influencing factors and considerations

The fabrics with big influence are mainly T/C type fabrics with low weight per square meter, loose weave structure, large horizontal and longitudinal elasticity, improper softness, either pile or no pile, or hanging button (terry is picked up but not cut off). Auxiliary factory will only give the marketing of a single pile agent, do not understand the root cause of bad pile.

Pile agent: the industry is familiar with the practice of low yellowing soft film compounded with less than 10% of dimethyl silicone oil emulsion (also known as pile oil), this pile agent formula can only provide a smooth and fluffy feel, there is no role for this kind of buckle pile fabric.

For each square meter weight large weave structure tight cotton terry and towel cloth, loose good soft piece, with a little high ammonia value silicone oil and dimethyl silicone oil emulsion (pile oil), once on the hair feather rich.

T / C fabric certainly do not use amino silicone oil, amino silicone oil resilience and viscosity of the pile will play a counterproductive role, will increase the fluffy fabric slip and elasticity, increase the pile fabric hanging buckle and the chance of tearing cloth, sometimes feel the fabric has been very soft, but not pile or hanging buckle.

T / C fabric correct soft method is: soft sheet compounded with dimethyl silicone oil emulsion use, and then with a little multifunctional finishing agent (also known as moisture wicking finishing agent).

Low per square meter weight pile fabric certainly do not do and soft and smooth, will greatly reduce the fabric strength, pile will tear the fabric, and fabric loose elasticity increase, easy to hang buckle; as long as the point on the loose smooth feel can be; thick fabric can do and soft and smooth, can reduce the number of pile.

Weaving factory because of various reasons did not use pile yarn to weave, produce up not pile or hang buckle phenomenon, but and weaving structure loose or due to inappropriate soft program caused by the fabric loose elasticity increase produce up not pile and hang buckle phenomenon is different, can not be confused.

Thin, short, dense pile type pile process

Pile finishing is the surface of the fabric fiber exposed to increase the thickness of the fabric, through the softener to improve its feel and enhance its insulation properties.

The pile process directly determines the style and quality of the fabric, through the pile finishing of the fabric, can significantly improve the appearance and feel of the fabric, improve the warmth and usefulness of the fabric.

In this project, by selecting suitable fabric structure, improving tension manipulation and shearing device, and conducting in-depth research on factors such as pile pulling strength, pile pulling sequence and pile pulling times, we have developed thin pile fabrics with short and dense and good application properties.

Raw material selection

The fabric of this project contains base fabric layer and terry layer, where the base fabric layer is woven by the fiber cross-section is usually general polyester filament, spinning yarn density wei 0.22~0.33 tex; terry layer is woven by super fine denier, fine denier or functional polyester filament, terry layer will completely wrap the base fabric layer, showing the reverse wrap structure, the fabric structure is tight, increasing the difficulty of pulling comb shear, overcoming the light thin fabric in pulling pile It overcomes the problems of straight hair pulling, hole defects and poor expansion of light fabric.

Device optimization

Improve the tension manipulation device

The unstable tension manipulation of the pile machine will cause the fabric pile quality to be unstable, which will cause the pile to be broken and affect the fabric pile, so the incoming tension manipulation device and the outgoing tension manipulation device of the pile machine are improved. Through device improvement and process optimization, we developed a thin pile fabric, which has short and dense pile, fewer defects on the fabric surface, and excellent handfeel and application performance.

a. Feeding tension manipulation device

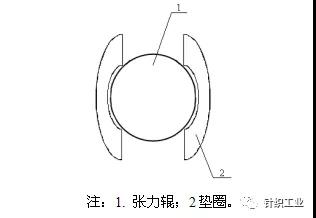

△Improved feed tension control device

The improved cloth inlet tension manipulation device holds the bearing through the oil pressure manipulation washer 2 to produce the damping tension effect, and the fabric moves on the passive tension roller 1 to drive the passive tension roller 1 to run, thus producing tension, which is controlled by the damping force of oil pressure manipulation. In order to prevent the fabric from slipping on the passive tension roller, it can be wrapped with anti-slip rubber outside the passive tension roller.

b.Tension manipulation device of the fabric outlet roller

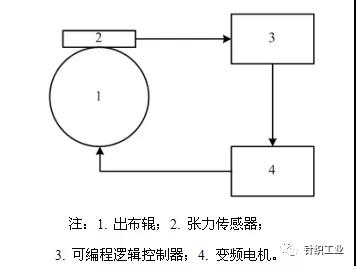

△Improved tension control device for the exit roller

The improved tension manipulation device of the exit roller measures the fabric tension by the tension sensor installed on the exit roller, and feeds the measured tension to the PLC at the same time, and can manipulate the motor speed of the exit roller by setting the tension value on the PLC to precisely manipulate the tension on the fabric on the exit roller. Among them, there are options of rotational speed manipulation and tension manipulation on the PLC, which can solve the tension manipulation methods for different elasticity fabrics to achieve stable quality of fabric production.

Shearing machine cutter head spreading device

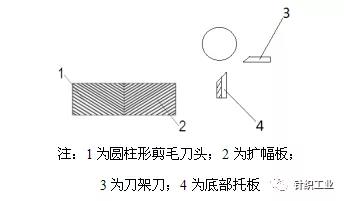

△Shearing machine head spreading device

Shearing machine head spreading device

The new kind of shearing machine cutter head spreading device has two advantages: with the assistance of this device, the rolled edge of the fabric can be peeled flat, so that the shearing effect of the fabric edge is also as stable and the amount of waste fabric can be reduced; it can reduce the probability of producing holes in the shearing process.

Fabric development process

The process flow is: pilling → combing → shearing.

Wool pulling process

The 2% pile agent is selected, and the sequence of 3 light pulls, "reverse side → front side → reverse side → front side → reverse side → front side" is determined.

Carding process

This project selects the medium reverse hair combing process.

Shearing

Shearing knife distance is the main factor to manipulate the shearing height, after several tests, the shearing tension, brush distance, shearing knife distance and other process parameters to optimize, and finally determine the frontal shearing process parameters for the hair direction: along the hair, shearing tension: 2.5 kgf, out of the cloth speed tension: 1.5 kgf, knife distance: 0.8/0.15 inch, knife speed: 850 r/min, brush distance: 2.5 inch Brush speed: 50 r/min.

Brushing, brushing, gripping and bristling?

1. Brushing

means rubbing on the fabric surface with abrasive rollers or metal rollers.

Different fabrics are combined using different sanding mesh to achieve the expected brushing effect.

The general principle is to use high mesh sanding for high count yarn and low mesh sanding for low count yarn.

Sanding rollers are used for forward and reverse rotation, and generally an odd number of sanding rollers are used.

The factors that affect the effect of sanding are

Grinding roller speed, speed, moisture content of the cloth, covering angle, tension, etc.

2. Hair grabbing

is to use a certain angle of the steel wire bending needle into the spinning yarn inside, hook out the fiber, forming hair feathers.

and hair pulling is the same meaning, different words only.

Different fabrics use different steel needles, there are round and pointed, in general, cotton with a pointed, wool with a round head.

Influencing factors

Speed, needle roller speed, needle roller number, moisture content, tension, needle density, needle bending angle, twist of spinning yarn, pretreatment additives used, etc.

3. Brush hair

is the use of brush-like bristle rolls sweeping over the fabric.

Different bristle rollers are used for different fabrics and treatments, such as pig bristle brush, wire brush, carbon wire brush, ceramic fiber brush.

Simple processing using pig bristle brush, such as brushing cloth before burning; wire brush is generally needed for intense pile fabric, such as knitted fabric flannel; carbon silk brush is used for high-grade cotton fabrics, surface treatment requirements fine; processing requirements more fine use of ceramic fiber.

Influencing factors

Number of brush rolls, speed, stiffness of the brush wire, fineness of the brush wire, density of the brush wire, etc.

Difference between the three

Grab hair and hair pulling is a concept, that is, the same process, the equipment used is pulling machine, the adoption of steel needle roller will fabric spinning yarn microfiber pull out, forming the surface of the fluff effect, the specific products are velvet, silver hydroxyl tweed and so on, hair pulling process is also called "pile".

The equipment used in the brushing process is a brushing machine, which adopts sand, carbon, ceramic and other rollers to grind out the microfibers in the spinning yarn of the fabric to form the surface of the pile effect, compared with the brushed products, the brushed pile is short and dense, with a very fine feel.

Brushing is a special process for corduroy, because corduroy is made by cutting the weft yarn of the surface organization, and by brushing, the spinning yarn is broken up and formed into a huggable pile. The corduroy strip has a complete luster, so the post-brushing machine is also called waxing machine.

Contact: Jeanne yang(MISS)

Phone: 13912652341

E-mail: [email protected]

Add: Room A2216/A2217,Double-Star Building,No 567 New South Middle Road, KunShan City JiangSu Province ,China.