Bamboo yarn

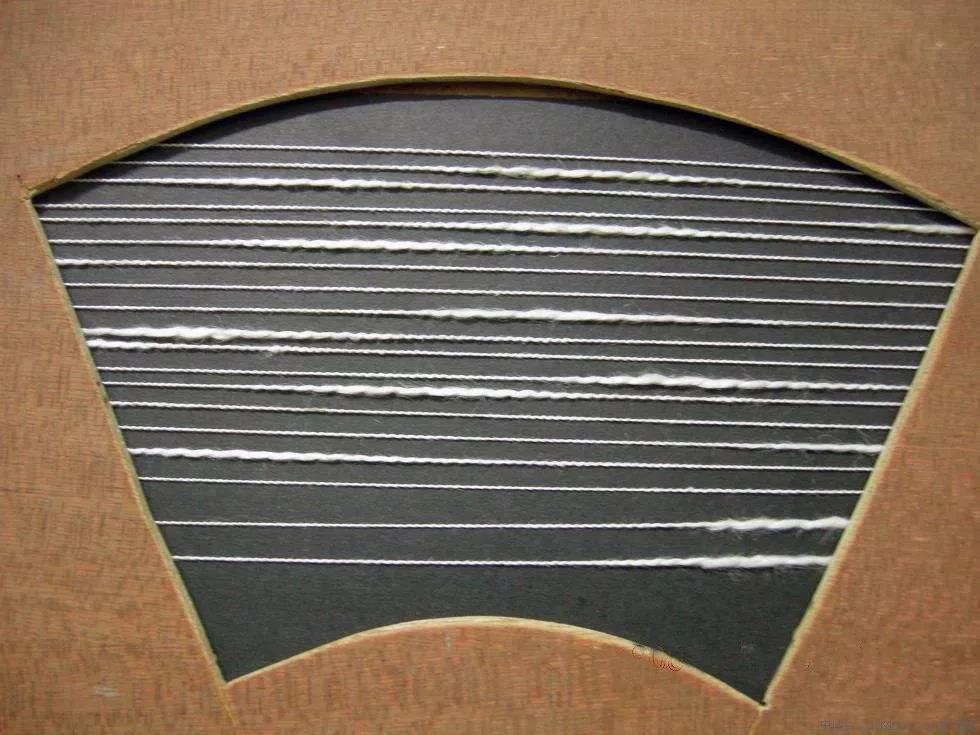

The spinning yarn is thin and thick, with a section stacked out called bamboo knot.

Bamboo knot was originally a common fault in the production of fabric, due to the spinning process, such as drafting, uneven thickness and other issues to influence the spinning yarn local unevenness of fineness, the formation of similar bamboo knot like a bump, produce bamboo knot defects, affecting the quality of the fabric.

However, when this similar to the bamboo knot like bump in the fabric surface to form a uniform distribution, can make the fabric surface to form a very literature, produce a unique fabric style, to meet people's requirements for fabric fabric style diversification. So in the spinning process thought of so that the spinning yarn density in the direction of its length occurs in a regular or irregular change, obtained the bamboo yarn, and this spinning yarn for the production of fabric, the formation of bamboo yarn fabric.

01

Bamboo yarn characteristics

With the appearance of uneven distribution of thickness and fineness, it is one of the fancy yarns with many types, including coarse detail-like bamboo yarn, lump-like bamboo yarn, short fiber bamboo yarn, and filament bamboo yarn. Bamboo yarn can be used for light summer fabrics and heavy winter fabrics. It can be used for clothing fabrics and decorative fabrics, with outstanding flower patterns, chic styles and strong sense of standing body.

02

Bamboo yarn formation principle and method

Principle.

In a normal spinning machine, an additional device is added to make the front roller change speed or stop, thus changing the normal drafting multiplier and suddenly producing a thick knot in the normal yarn, like a bamboo knot, thus called bamboo yarn.

Method.

Adopt electromagnetic clutch to operate the front roller stop method

When spinning the base yarn: The clutch is in a suction state to keep the front roller in normal operation.

Spinning coarse section: the clutch is de-energized, the dynamic plate and the static plate are disengaged, so that the front roller is stopped.

The front roller is stopped + the middle and rear rollers are still running. The fiber sent out is piled up between the middle roller and the front roller.

When the clutch is re-energized, the front roller starts to run again, taking the accumulated fibers away and forming a bamboo knot in the base yarn.

The front roller stops immediately for a long time. More fibers are accumulated. The bamboo knot is thicker.

This method is suitable for thicker bamboo knots.

It is also possible to make a sudden overfeed of the back roller, which also changes the drafting times and creates a bamboo knot.

Stepper motor driven front roller speed change method, servo motor driven middle and rear roller overfeed method, etc.

When using front roller speed change to produce bamboo yarn, the sensitivity is high, and it is suitable for producing denser bamboo knots, and the length and thickness of bamboo knots can be better manipulated.

Front roller variable speed? It affects the yield

The speed of the front rollers is constant from time to time + the spindle speed is constant? It also has an effect on the twist degree

When producing bamboo yarn with the middle and rear roller overfeed, it is not as sensitive to produce short and dense bamboo knots as the front roller variable speed, and it is also more expensive to manufacture.

Caution

When producing bamboo yarn, the centrifugal force at the bamboo knot is greater, and the air ring is larger and smaller at times during production, so the wire ring is selected with a preference for grasp. At the same time, due to the increase in the thickness of the bamboo knot, through the steel wire ring there are certain difficulties, so should choose to use a large circle of steel wire ring.

If the front roller stopping or variable speed is adopted to produce bamboo yarn, the twist degree should be low.

The production of intensive bamboo section, because the speed of the front roller is constantly changing, so the speed should be slowed down appropriately, otherwise it will increase the whole machine head breakage rate.

When manually stopping the yarn, it is better to stop at the base yarn part to avoid the coarse knots, otherwise the twist degree at the coarse knots will increase the head breakage when driving.

03

Application of bamboo yarn

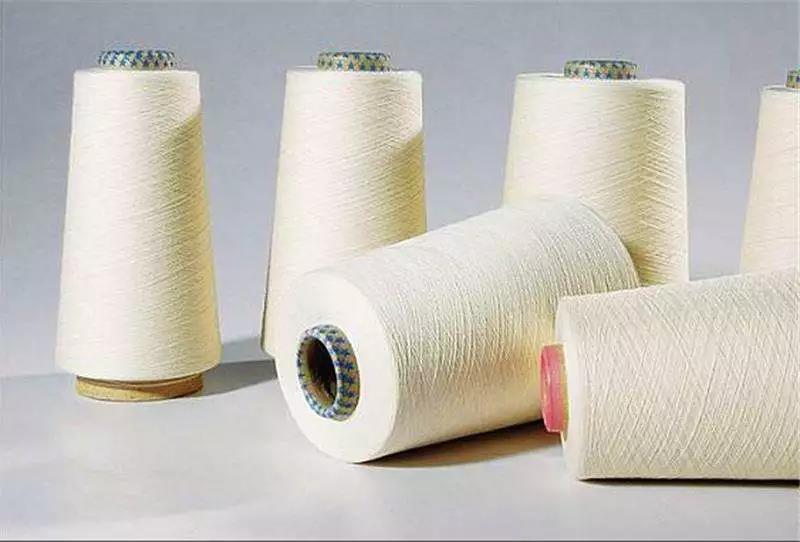

Currently, the commonly used yarn is 12-84tex (12-83 metric). The raw materials are pure cotton, chemical fiber blended chemical fiber fabric yarn, mainly staple fiber yarn, but also medium-length and wool type fiber, etc.

The length of bamboo knots generally can not be smaller than the length of the fiber. Therefore, the length of bamboo knots spun with cotton fibers is shorter, while the length of bamboo knots spun with woolen fibers is longer.

The thickness of the bamboo knots, depending on the species .

Because the difference between the thickness of the thick knot and the base yarn is too large, the twist is very small, making this section of yarn not only easy to hairy, but also low strength. Knitted fabrics or woven fabrics made of this yarn have a rough surface and unique style. This yarn is also used to make wave yarn on fancy twisting machine, because the waveform at the thick section is very large, shaped like corn, so it is also called popcorn yarn.

04

The relationship between the main parameters of bamboo yarn and fabric style

Bamboo yarn parameters include base spinning yarn density, bamboo knot thickness, bamboo knot length and bamboo knot spacing, and because of the very structure of bamboo yarn, the fabric style and the above 4 parameters are closely related;

Its various combinations decide its very style on the cloth, and its methods are mainly the following 4 kinds.

1. Because the bamboo section of bamboo yarn is thicker, the twist added to the bamboo section during spinning is also less, and the bamboo section fiber is looser, which makes the coarse section and the fine section of bamboo yarn inconsistent in drawing the dye when it is colored, and then depending on the length of bamboo section will form the style of drizzle or raindrop.

2. Different raw materials form different styles: for example, bamboo knots are more obvious in bamboo yarn fabrics made of single yarn spun from general cotton and polyester raw materials.

And the adoption of shaped fibers such as cationic polyester, strong finish polyester, viscose, etc. to form finer bamboo knots, and then and general yarn twisted into a line, can be made into high-grade fabrics.

3. in the rotor spinning machine spinning 48.6 ~ 58.3tex (Nel2 ~ 10) bamboo yarn, its bamboo knots can be higher than the normal yarn 1.3 ~ 1.8 times, with bamboo knot spacing and length changes, can be woven with a hemp style of high-grade fabrics.

4. Using the different length, thickness, pitch and raw materials of the bamboo section of bamboo yarn, we can develop colorful and different styles to meet the needs of all kinds of different consumers.

05

The base yarn number and comprehensive number of bamboo yarn

The common number of bamboo yarn is usually named by the base yarn number, such as C14.5tex bamboo yarn refers to the number of bamboo knot spacing ask normal yarn, and the number at the bamboo knot is larger. In actual production in the front roller variable speed spinning bamboo section, generally set a good base yarn high speed value and twist value spinning out of the normal base yarn number before setting the low speed value and other bamboo section parameters to produce bamboo yarn.

The integrated number of bamboo yarn refers to the integrated number of base yarn and bamboo yarn. Generally, there is a difference between the process design and the actual integrated number spun, and the size of the difference between the integrated number of bamboo yarn spun by different types of bamboo yarn devices is also different. The integrated number is an important basis for daily manipulation of spun yarn weight deviation in production, and is also the main indicator for accounting of cotton cost for bamboo yarn. Some companies use the base yarn number to manipulate the deviation of spun yarn weight when spinning bamboo yarn, so that the actual base yarn number spun is lighter and more meters of cloth can be woven. This is fine for bamboo knot thin yarn, but for bamboo knot thick and dense bamboo knot yarn, will make the base yarn at too fine and cause more finishing breaks.

The design integrated number refers to the integrated number of bamboo knot yarn designed by the process. It is the weighted average of the base yarn and the bamboo yarn number corresponding to the percentage of the pitch and the length of the knot in the definite cycle as weights.

It should be noted that the total length of the yarn in a definite cycle should be calculated by the regularity of the arrangement of bamboo knots.

For regularity, it is the cycle length in one cycle, e.g. five bamboo knots in one small cycle; for irregularity, it can be estimated according to the set average knot length, pitch and coarseness multiplier.

The actual integrated number is the actual number of spun bamboo yarn, and the process design integrated number is a gap, so daily production in accordance with the national standard for spinning yarn, daily test manipulation into the actual integrated number of yarn to achieve or close to the process design integrated number, the weight deviation manipulation in ± 2.5%, the monthly deviation manipulation in ± 0.5%.

Contact: Jeanne yang(MISS)

Phone: 13912652341

E-mail: [email protected]

Add: Room A2216/A2217,Double-Star Building,No 567 New South Middle Road, KunShan City JiangSu Province ,China.